So individuell wie ihre anforderungen

Automatisch gut

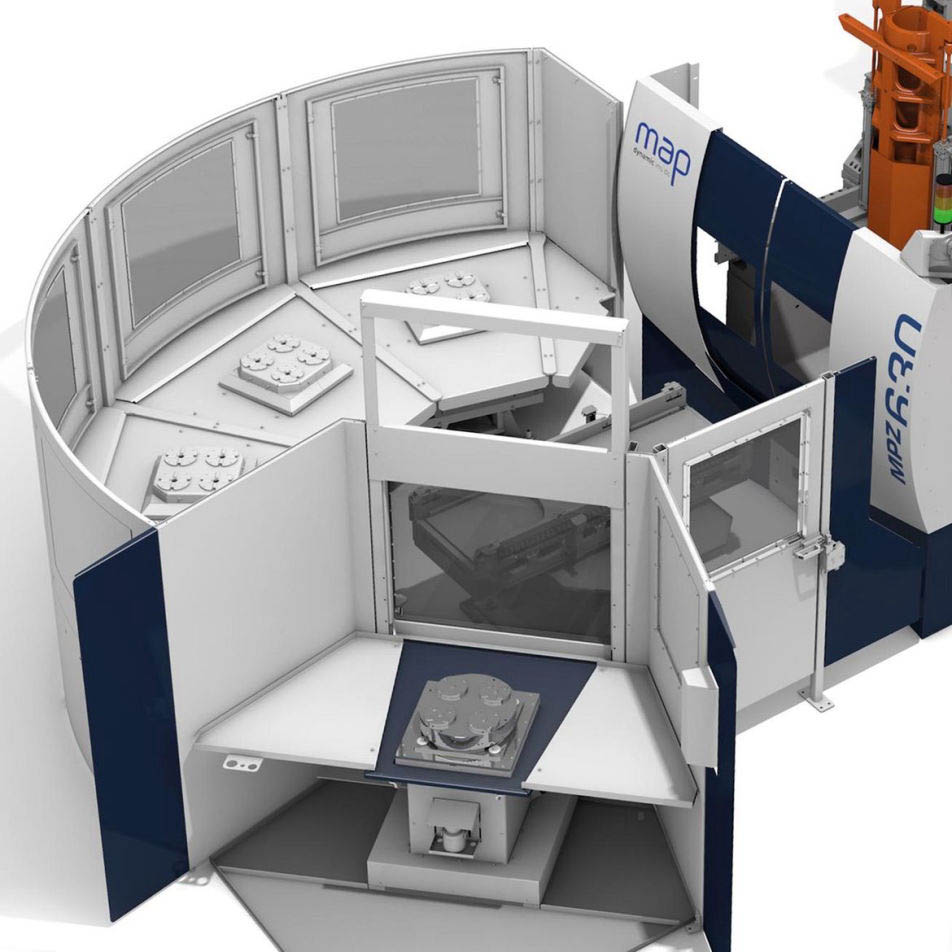

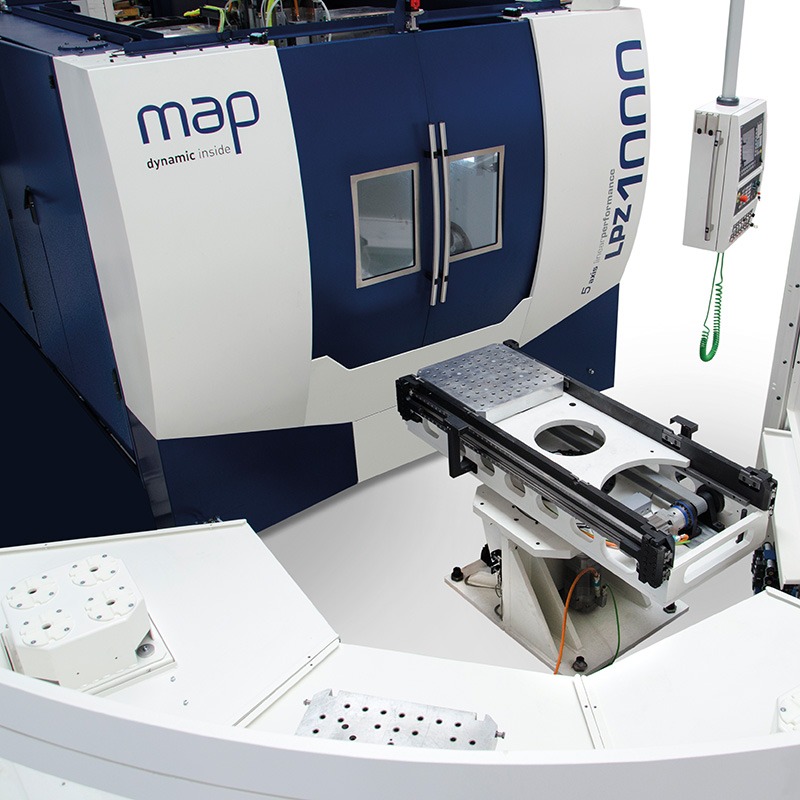

Automatisierung ist für uns ein wesentlicher Teil der Maschinenkonzeption im Kontext vieler realisierten Kundenlösungen.

MAP hat sich bereits seit Jahren darauf eingestellt und eine Vielzahl von Automationslösungen erfolgreich entwickelt und realisiert.

Von der Planung bis zur Realisation erstellen wir für Sie ganz individuelle Lösungen, die Ihnen echte und nachhaltige Produktionsvorteile bieten. Gerne beraten wir Sie, wie Sie zukünftig wirtschaftlicher produzieren können.